5S is likely one of the first equipment that may be implemented in an organization this is beginning down the trail of a continuing growth tradition. A 5S implementation is helping to outline the primary regulations to get rid of waste and deal with an effective, secure, and blank paintings atmosphere. It was once first popularized by means of Taiichi Ohno, who designed the Toyota Manufacturing Device, and Shigeo Shingo, who additionally put ahead the idea that of poka-yoke.

The 5S technique is straightforward for everybody to start out the usage of. It doesn’t require any technical research and will also be applied globally in all varieties of firms, starting from production vegetation to workplaces, small companies to very large multinational organizations — and in each personal and public sectors. Its simplicity, sensible applicability, and visible nature make it an enticing assist for operators, administrators, and consumers alike.

The 5S Technique

The 5S technique is split into 5 steps crucial for attaining its objectives. We will be able to speak about each and every step intimately.

Be told free of charge! Subscribe to our YouTube Channel & Be a A part of the 400k+ Glad Newcomers Neighborhood.

Type:

Step one within the 5S technique is to type. This step comes to figuring out the vital pieces to your workspace and getting rid of any extra or useless pieces. This is helping to scale back muddle, decrease distractions, and streamline the workspace.

The second one step is to set it so as. This step comes to organizing the vital pieces logically and systematically. This comprises assigning a particular location for each and every merchandise and labeling them for simple identity. This is helping to scale back seek time and get rid of the will for extra stock.

The 3rd step within the 5S technique is to polish. This step comes to cleansing and keeping up the workspace. This comprises common cleansing, inspection, and upkeep to verify the whole lot is in operating order and defects-free.

The fourth step within the 5S technique is to standardize. This step comes to developing a collection of pointers and procedures for keeping up the workspace. This comprises documenting the former 3 steps and organising a typical time table for his or her implementation.

The overall step within the 5S technique is to maintain. This step comes to making a tradition of continuing growth, the place the former 4 steps are constantly adopted, and the workspace is constantly optimized.

Advantages of 5S Technique:

The 5S technique supplies a lot of advantages to organizations that undertake it. One of the most advantages come with:

- Stepped forward productiveness

- Decreased waste

- Enhanced protection

- Higher worker pleasure

- Stepped forward buyer pleasure

- Stepped forward high quality

- Decreased prices

Why Use the 5S Technique?

5S is a strategy for developing an arranged and productive workspace by means of sorting, straightening, shining, standardizing, and maintaining. The usage of 5S as a basis, complex processes and equipment to enforce lean manufacturing will also be advanced.

5S is the easiest instrument to spot the primary growth initiatives to your corporate to get rid of waste. Even supposing now and again seen as a house responsibilities method, it’s in fact an leading edge control device that is helping folks assume lean, paving the best way for the adoption of Lean rules within the group. Working out the 5S technique is likely one of the foundations of Six Sigma rules, and will also be extraordinarily advisable for organizations of a wide variety.

A Black Belt makes use of 5S to seek out waste, reorganize workflows, and advertise a tradition of continuing growth as a part of the Six Sigma toolbox. Their skillability in fusing Six Sigma methodologies with Lean rules is helping them to direct enterprises towards advanced output and high quality. A Six Sigma Black Belt begins the method of optimization by means of intentionally imposing 5S, laying the groundwork for in depth adjustments and long-term good fortune.

And right here’s the most efficient section: imposing 5S is a breeze! With this logical, step by step information, you’ll be informed what the massive deal about 5S is, devise an motion plan for 5S implementation, and the way very best to wield this tough instrument for advanced productiveness, removal of wasteful processes, and all-around construction!

Professional Tip: For extra on harnessing the rules of Six Sigma for place of work and private productiveness, right here’s an insightful article that investigates techniques to fortify efficiency the usage of the rules of Six Sigma.

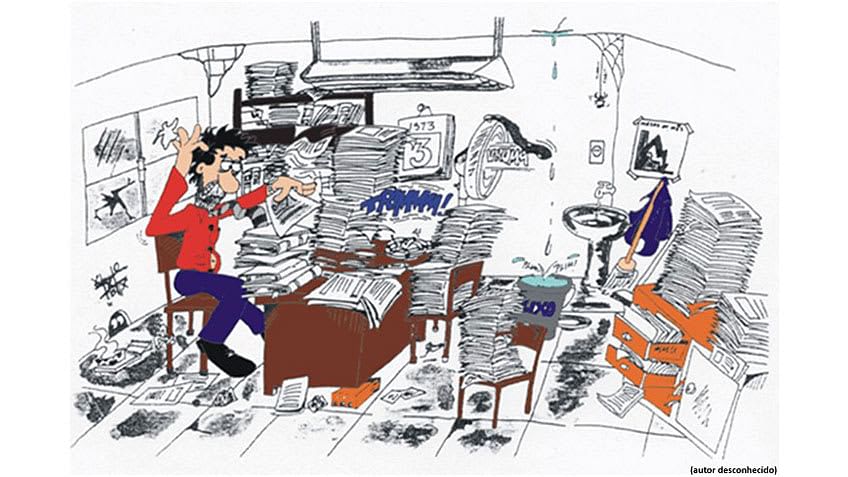

Sooner than 5S Implementation

After 5S Implementation

Implementation Methods:

Imposing the 5S technique calls for cautious making plans and execution. Some efficient methods for imposing the 5S technique come with:

- Shape a devoted crew to supervise the implementation procedure.

- Supply good enough coaching to workers to make certain that they perceive the technique and its advantages.

- Get started with a pilot mission and progressively increase to different spaces of the group.

- Determine transparent metrics to measure the good fortune of the implementation.

- Regularly observe and toughen the technique to verify its effectiveness.

5S Implementation Plan

Step 1: How Smartly is Your Trade Doing?

Our cartoons above lend a hand illustrate how 5S can receive advantages your company. Sooner than you get began, let’s carry out a check. In case you resolution sure to any of the next questions, you could in finding 5S in reality helpful and efficient:

- Do folks to your place of work battle to find paperwork or information, whether or not in bodily or virtual structure?

- Are there free, sagging electric cables within the place of work?

- Are there information, drawers, and cupboards which might be unlabeled, or do they comprise unmarked content material this is exhausting to spot?

- Is effective house taken up by means of pointless pieces?

- Are there papers to your place of work that aren’t used and are accumulating mud?

- Does everyone understand how to stay the place of work arranged and are absolutely conscious about their roles and obligations?

In case you spoke back sure to any of those questions, 5S could also be precisely what you want!

Step 2: The 5S Technique: Damaged Down

What Does 5S Stand For?

The title 5S refers to a collection of 5 phrases borrowed from Eastern, all starting with the letter S when transliterated. The identical phrases in English additionally start with an S. In essence, those 5 phrases constitute the 5 steps towards operational and procedure excellence:

-

Type:

Separate required equipment, fabrics, and directions from those who aren’t wanted. Take away the whole lot that’s not vital from the paintings house.

-

Retailer:

Type and arrange all equipment, apparatus, information, information, subject material, and assets for fast, simple location, and use. Label all garage places, equipment, and kit.

-

Shine:

Set new requirements for cleanliness. Blank and take away all trash, grease, and mud. The whole thing should be blank, tidy, and well installed its suitable position. Cleanliness supplies a secure place of work—and makes doable issues noticeable, e.g., apparatus leaks, free portions, lacking guards, free forms, or fabrics.

-

Standardize:

Interact the group of workers to systematically carry out steps 1, 2, and three above day-to-day, to deal with the place of work in highest situation as a normal procedure. Determine schedules and set expectancies for adherence.

-

Maintain:

Make 5S a part of your tradition, and incorporate it into the company philosophy. Construct organizational dedication in order that 5S turns into considered one of your organizational values and everybody develops 5S as a addiction. Combine the 5S technique into the efficiency control device.

Step 3: The Motion Plan

You’ll be able to get started imposing 5S by means of offering coaching in your group of workers to know the device. This can be adopted up with one-day classes with each and every worker or crew to verify they’re at the identical web page so far as implementation is anxious.

Within the first one-day consultation, workers will have to glance be in a position to fulfill the primary 3 5S necessities:

- Take an image of the present standing of your place of work.

- Type to split the rest this is wanted and vital from what isn’t wanted.

- Prepare the issues you want so that there’s a position for the whole lot and the whole lot has a spot. You will have to be capable to in finding the rest in only a few seconds.

- Blank the place of work and eliminate issues that make it tricky to deal with cleanliness, akin to containers at the ground that save you you from having the ability to blank all of the floor — label them and retailer them in classified drawers, as an alternative.

- Get ready an motion plan for the pieces you aren’t ready to maintain that day, however will be capable to within the close to long run. This might come with promoting pieces you now not use, donating them, recycling, or throwing them away.

- Take a 2d image after all of the day’s paintings, for evaluation.

Professional Tip: Learn to follow those rules and get a certification to turn for it with a certified Lean Six Sigma Certification Direction!

Step 4: Standardize

All over the second one one-day consultation, two weeks later, workers will have to take the 3rd image and examine it to the primary two photographs. Many organizations arrange peer audits to test how the 5S rules are being met in addition to to verify the plan is transferring ahead. Paintings in combination to outline techniques to standardize the enhancements through the years: arrange cleansing schedules, outline roles and obligations, and get ready written procedures or diagrams to lend a hand everybody take into accout what to do.

Step 5: Maintain

All over the 3rd one-day consultation, two months later, test to look how your place of work appears to be like and time table any other peer evaluation. This manner, you’ll be able to be sure the 5S are sustained by means of making sure outlined schedules are being met and everyone seems to be following the procedures.

- Purple Tags: Those are used to label pieces which might be now not wanted or aren’t in use. Purple tags lend a hand within the sorting procedure.

- Shadow forums: Those are used to arrange equipment and kit. The shadow board has an overview of the instrument or apparatus, making it simple to spot if one thing is lacking.

- Visible controls: Those are used to make it simple to spot the proper location for equipment and kit. Examples come with colour coding, labels, and indicators.

- Cleansing checklists: Those are used to make certain that the workspace is blank and tidy. The tick list is helping in keeping up the shine side of 5S.

- Standardized paintings procedures: Those are used to make certain that everybody follows the similar procedure for appearing duties. Standardized paintings procedures lend a hand within the standardization side of 5S.

- Flooring marking tape: That is used to mark obstacles, aisles, and garage places. Flooring marking tape is helping within the set-in-order side of 5S.

- Kanban techniques: Those are used to regulate stock ranges. A Kanban device is helping deal with the appropriate stock degree, making sure no waste of assets.

- Visible control forums: Those are used to show key efficiency signs (KPIs) and growth towards objectives. The visible control board is helping in maintaining the enhancements made thru 5S.

5S and Lean Production

5S technique is a a very powerful instrument throughout the Lean Production philosophy, which goals to maximise worth whilst minimizing waste. The 5S device supplies a structured method to organizing the place of work, bettering potency, lowering mistakes, and lengthening productiveness. Via lowering waste and optimizing workflow, 5S helps the entire purpose of Lean Production, which is to create worth for the buyer whilst minimizing assets and time. Incorporating 5S into the Lean Production procedure can lend a hand organizations succeed in steady growth and sustainable good fortune.

Be told the DMAIC technique with real-world case research and the abilities you want to lend a hand your company develop with our Lean Six Sigma Inexperienced Belt certification on-line program aligned with the IASSC examination.

Conclusion

Simplilearn’s skilled coaching lessons are facilitated by means of qualified professionals with a few years of revel in of their respective fields. And, our lessons are designed that will help you cross your examination at the first take a look at. Are you in a position to start out? Just right good fortune! If you wish to be informed extra about lean methodologies and Six Sigma, take a look at this 5-minute video. It’s an advent to Qualified Lean Six Sigma Inexperienced Belt and gives you a style of Simplilearn’s on-line coaching.

FAQs

1. What’s the 5S technique?

The 5S technique is a place of work group device that goals to toughen potency and get rid of waste by means of keeping up a blank and arranged paintings atmosphere. The 5S’s stand for Type, Set so as, Shine, Standardize, and Maintain.

2. What’s the objective of 5S?

The aim of the 5S technique is to toughen place of work potency and productiveness by means of making a blank, arranged, and secure paintings atmosphere. It goals to get rid of waste, cut back mistakes, and build up worker pleasure by means of offering a transparent and structured device for organizing workspaces and fabrics.

3. What’s the sixth S?

Whilst the 5S technique historically is composed of Type, Set so as, Shine, standardizing, and Maintaining, some practitioners have added a 6th “S” – Protection. Protection is a important element of place of work group, and making sure that workers paintings in a secure atmosphere is very important for his or her well-being and productiveness. Together with Protection because the 6th “S” guarantees that it’s given equivalent significance and attention within the general place of work group device.

4. How does 5S relate to kaizen?

The 5S technique is steadily used as a foundational instrument throughout the Kaizen steady growth philosophy. The 5S device supplies:

- A structured way for figuring out and getting rid of waste.

- Lowering mistakes.

- Bettering productiveness, which might be all important elements of the Kaizen way.

The usage of 5S helps and reinforces the continuing Kaizen mindset of continuing growth.

supply: www.simplilearn.com